Grandfather clocks are marvels of mechanical engineering, intricate systems where countless components work in precise harmony to measure time and deliver their signature chimes.

When one of these majestic timepieces falters, repairing it often involves a delicate understanding of its internal anatomy and the specific function of each part.

The success of a repair hinges not just on the skill of the horologist, but critically on the availability, quality, and accurate installation of the correct replacement grandfather clock parts.

This article will explore the pivotal role these individual components play in restoring a grandfather clock to its former glory.

The Heart of the Matter: The Movement Components

At the very core of every grandfather clock lies its movement, a complex assembly of gears, plates, pivots, and springs. These are the components that actually keep time. When a clock stops or runs erratically, the issue often stems from wear, dirt, or damage within this intricate system.

Replacing a worn pivot, a broken gear tooth, or a fatigued mainspring with high-quality Grandfather Clock Parts is essential. Each component within the movement must fit perfectly and operate smoothly for the clock to function with its characteristic precision and reliability.

The Powerhouse: Weights and Pulleys

Grandfather clocks are typically weight-driven, meaning heavy weights slowly descend, providing the power that drives the movement and the chime train.

The proper functioning of these weights relies on intact cables or chains and smooth-running pulleys. If a cable frays or breaks, or a pulley becomes seized or damaged, the clock loses its power source.

Sourcing durable and correctly sized grandfather clock parts, such as replacement cables, chains, or brass pulleys, is fundamental to re-establishing the clock’s energy transfer system and enabling it to run continuously.

The Voice: Chime and Strike Mechanisms

The melodic chimes and powerful strikes are what give a grandfather clock its unique character. These sounds are produced by a separate train of gears, hammers, and chime rods or bells. Common issues include weak or silent chimes, or hammers striking improperly.

Repairing these involves inspecting and, if necessary, replacing worn chime hammers, bent arbors, or damaged chime rods. The precise calibration and installation of these specific grandfather clock parts are crucial to restoring the clock’s beautiful voice to its original clarity and rhythm.

Stability and Regulation: Pendulum and Escapement

The pendulum is the clock’s regulator, dictating the pace at which the clock runs. Its consistent swing is controlled by the escapement, a delicate mechanism that translates the power from the weight train into the precise ticking motion.

Any wear or damage to the pendulum’s suspension spring, the escapement wheel, or the pallet forks can cause the clock to run fast, slow, or stop altogether.

Replacing these critical grandfather clock parts with precision-engineered equivalents is vital for restoring the clock’s timekeeping accuracy and ensuring its stable operation.

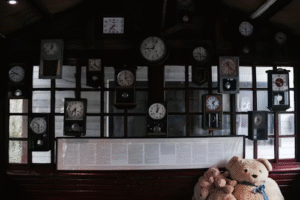

The Face and Hands: Dials and Aesthetics

While the internal mechanisms ensure function, the dial and hands are what make the clock aesthetically pleasing and readable. Over decades, dials can become faded, cracked, or corroded, and hands can bend or break.

Restoring the visual appeal often involves repairing or replacing these exterior grandfather clock parts. A new or refurbished dial and a matching set of hands can significantly enhance the clock’s beauty and legibility, making it once again a proud centerpiece that accurately displays the time.